From The Daily Telegraph of the UK

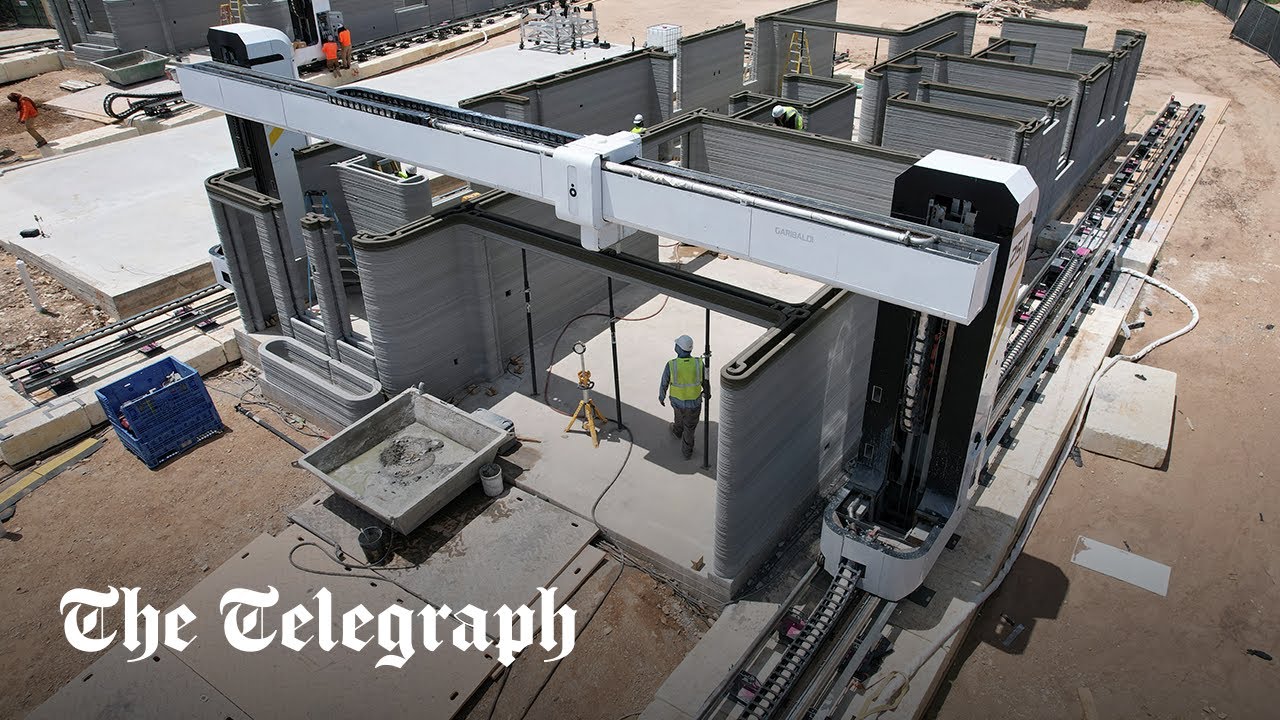

The walls of the houses are literally printed by a gigantic machine. (I have reproduced the article below, as it may be behind a pay wall.)

The finished product looks like a prefab house to me, but much sturdier, since the walls are made of concrete!...

___________

Watch: 3D-printer

completes final homes in world’s largest printed neighbourhood

Printing offers a

faster, cheaper and less wasteful way to build new housing

8 August 2024 •

In Texas, a towering

45ft robot is putting the finishing touches on what is thought to be the

world’s largest 3D-printed neighbourhood.

Icon, the developer

behind the project, is printing off its 100th house at Wolf Ranch in Georgetown

this summer, less than two years after kicking off the project.

It takes around three

weeks for work on each home to be completed.

Concrete powder, water,

sand and other additives are mixed together and pumped into a 4.75 tonne

printer called Vulcan.

The mixture is then

piped like icing through a nozzle along a pre-programmed path, layer-by-layer.

The resulting appearance of the walls is likened to corduroy.

Printing off homes in

this way is faster,

cheaper, requires fewer workers and minimises waste, according to the company.

Senior project manager

Conner Jenkins said: “It brings a lot of efficiency to the trade market. Where

there were maybe five different crews coming in to build a wall system, we now

have one crew and one robot delivering that scope. [There’s] the same advantages

for the supply chain system.

“We hope that as we

[consolidate] these different systems, we can bring down volatility in the

housing market.”

Printed homes at Wolf

Ranch are priced from around $450,000 (£353,510) to roughly $600,000. They

range from 1,500 to 2,000 sq ft and consist of either three or four bedrooms in

a single-storey floorplan.

Residents Lawrence

Nourzad and Angela Hontas, who bought a printed home at the ranch earlier this

summer, compared their new house to a “fortress”.

Mr Nourzad said the

walls are solid enough to “go head-on with maybe an F2, F3 tornado and be pretty resilient”. They were praised for keeping the

interior cool in the Texas heat, but criticised for causing connectivity

problems.

Mr Nourzad said: “These

are really strong, thick walls. That’s what provides a lot of value for us as

homeowners. But signal doesn’t transfer through these walls very well.”

The walls are designed

to be resistant to water, mould, termites and extreme weather.

While the walls are

printed, the foundation and metal roof are installed through traditional

construction methods.

For its next project,

Icon has been contracted by Nasa to built shelters and landing pads that are

suitable for the Moon’s surface.

_________

|

Watch: 3D-printer completes

final homes in world’s largest printed neighbourhood Printing offers a

faster, cheaper and less wasteful way to build new housing |

No comments:

Post a Comment